Meprotec combines AI-based software development and process engineering expertise to take the performance of production systems to a new level.

In addition to in-depth knowledge in the areas of Microsoft Azure Cloud, AI and software development, our team also has many years of practical knowledge in production, metallurgy and furnace manufacturing.

This has enabled us to achieve payback periods of one year for all customers!

PRODUCTS AND SERVICES

MEPROTEC ProDucesmart is revolutionizing process optimization for production lines in and outside of the metalworking industry. After the system or process chain has been digitized, bottleneck analyzes are carried out and AI-based models are created to optimize the largest cost drivers. This allows KPIs to be significantly improved and new optimization approaches to be created that cannot be recognized in normal everyday production.

Software Development

MEPROTEC offers support in the development and maintenance of your software solutions in the areas of Microsoft Azure Cloud, C #, ASP.Net, JS, WPF ... We support you with programming, cloud migration, data transmission and archiving as well as the creation of efficient online calculations . Based on the broad spectrum of experience and production know-how of our team, we can offer complete solutions from the technical problem to the tested software solution!

Industry 4.0 und Cloud Services

Long-term experience with software packages for cloud integration of industrial plants, online production calculations, the latest developments in the field of Industry 4.0 and proven concepts of vertical integration make MEPROTEC the ideal partner for your step into the digital future.

SUCCESS STORIES...

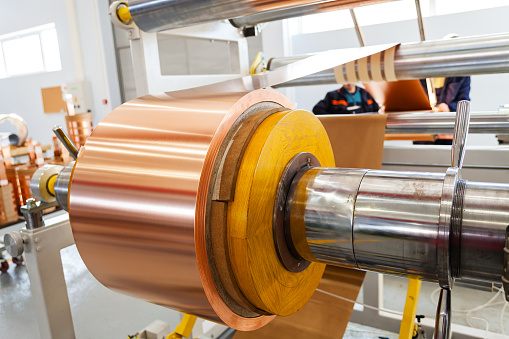

The implementation of MEPROTEC HFsmart in our hot forming system marked significant progress towards comprehensive quality control and process-oriented system operation. We were not only able to significantly reduce energy costs, but also noticeably reduce cycle times and roll consumption. These improvements gave us a significant competitive advantage through optimized throughput and cost savings. Thanks to MEPROTEC HFsmart , we can quickly and efficiently optimize production parameters for various components and react to quality fluctuations in real time.

Hannes Feuerhuber

CEO

weba Werkzeugbau Betriebs GmbH

As an occupational dermatology center, we were able to further develop the diagnosis and therapy of occupational skin diseases to the highest clinical and scientific standards with the individual software solution from MEPROTEC GmbH.

Large amounts of data were analyzed to determine risk factors for the development of skin diseases and preventive measures, diagnostics and therapeutic strategies were derived or optimized using artificial intelligence.

Ordensklinikum Linz Dermatologie

OÄ Dr. Barbara Ernst

Fachärztin für Dermatologie, Venerologie und Allergologie

Leitung Berufsdermatologisches Zentrum

Leitung Allergieambulanz

Ordensklinikum Linz - Elisabethinen

Krankenhaus der Elisabethinen Linz GmbH

After implementing the MEPROTEC HFsmart not only could resource-saving production and a reduction in CO2 emissions be demonstrated, but the assurance of component quality in the ongoing process was also improved. With MEPROTEC a total of 3 hot forming lines at Mubea were equipped with the MEPROTEC HFsmart and component testing for quality control was digitalized.

Michael Bienenda

Leiter Task Force TRPH

Mubea Tailor Rolled Blanks GmbH

MEPROTEC developed specific software for our company that allows us to extract data from Excel files, compare it with existing databases and prepare it for further use. This enables us to process marketing processes faster and more efficiently and to maintain high customer satisfaction.

Bernhard Jirenec

Deputy Managing Director

Roidl Versand GmbH

CONSULTING

Hot Forming & Heat Treatment

IT & Cloud

You have questions? We are happy to help you.